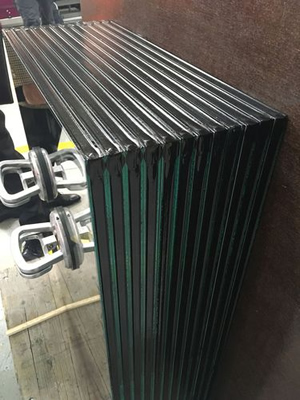

The new insulating glass line Velocity combines above-average quality and a high output. With a cycle time of only 16 seconds in the version Velocity Plus, the high-speed line manages the flash production of double insulating glass units in the dimension 900x600mm (triple glass units with only 26 seconds) with hot-melt sealing – this is the fastest plant for this type of processing currently available on the market.

This short cycle time complies with the market requirements especially for series insulating glass producers in the USA, Great Britain and South Korea.

In the standard version, the insulating glass line Velocity with a spacer applicator achieves a cycle time of 24 seconds for double insulating glass.

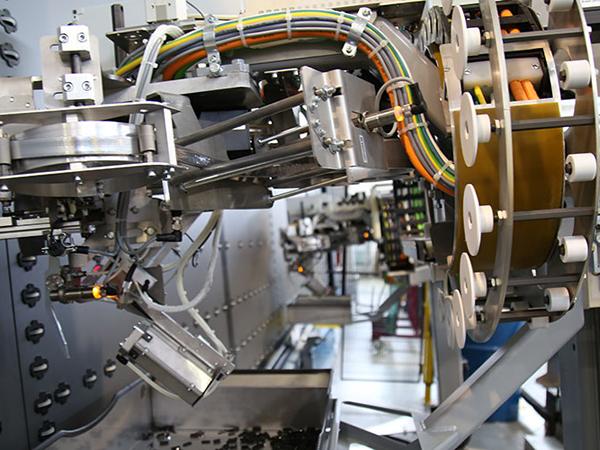

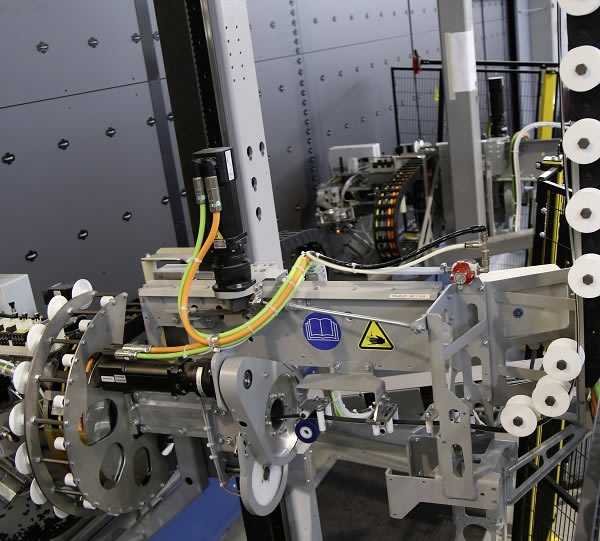

The Velocity Plus, on the other hand, has two spacer applicators that apply the spacers onto the glass sheet free from tension with the highest precision and quality.

In paired operation, the gas-filling press allows the simultaneous assembly of two insulating glass units with different sizes and thus a faster production with low investment costs.

The sealing plant with a highly precise dosing applies without interrupting the sealing strand and thus realizes the high quality as well as the low cycle time.

The Head of the Business Unit Insulating Glass Clemens Macarei and the Project Manager Sebastian Payrleitner are extremely proud of the newly developed Velocity: “With this line, we succeeded in developing a particularly sophisticated technical and extraordinarily economical solution.”

The new Velocity line will be presented live for the first time at the GlassBuild America in September 2017.

“We are proud to present the new Velocity line this year at the GlassBuild show and believe that this addition to the LiSEC product portfolio will provide greater flexibility in providing solutions for our customers,” states Bob Quast, CEO of LiSEC America.