After demonstrating the possibility of 3-D printing of glass components, KIT scientists have now developed a process for fabricating pure quartz glass that opens up possibilities for industrial use.

Glassomer can be milled, turned, lasered or processed in CNC machines – just like a conventional polymer

Glass is one of those unique materials that has been the subject of much discussion in the glass science community.

Glass research has advanced to the point where glass material can now be 3-D printed. Last year, scientists at Karlsruhe Institute of Technology (KIT) demonstrated 3-D printing of glass components using stereolithography with silica nanocomposite ink.

And earlier this year, researchers from Lawrence Livermore National Laboratory printed small glass pieces made from silica and silica-titania inks.

Now, KIT scientists have taken their glass research a step further. Head of the NeptunLab interdisciplinary research group of KIT’s Institute of Microstructure Technology Bastian Rapp and his research team have developed a process for fabricating pure quartz glass that opens up possibilities for industrial use.

“It has always been a big challenge to combine highly pure quartz glass and its excellent properties with a simple structuring technology,” Rapp says in a KIT news release.

“Glasses, and especially high-purity fused silica glasses are extremely difficult to structure,” team member Dorothea Helmer states in an Advanced Materials video.

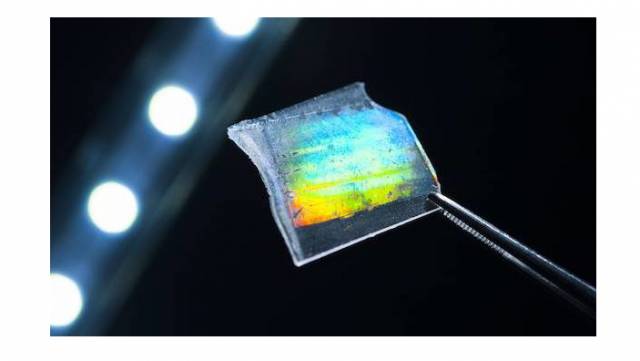

Rapp and his research team actually created a hybrid of sorts, by mixing glass with a polymer to fabricate a solid silica nanocomposite. Called (what else?) “Glassomer,” the new material offers the strength of glass while behaving like a polymer.

The researchers mixed quartz glass particles 40 nm in size with a liquid polyme...