For the use of the LineScanner on a tempering furnace – which is now also able to check anisotropy and edge stress in addition to geometry, surface quality, edge quality and also DMC codes - we have created a real masterpiece in regards to a visual, non-destructive tempering quality check.

Available LineScanner checks on a tempering furnace:

- Anisotropy / Isotropy

- Edge stress

- Surface quality

- Edge quality in the visible range

- Dimension check of overall size, cut outs, drill hole position and diameter

- DMC check

Isotropy / Anisotropy proportion

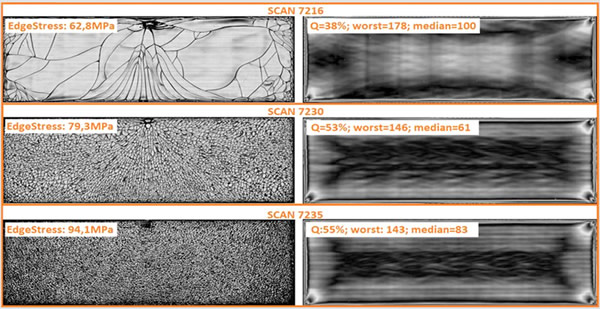

To get an exact measurement of the distribution of tensions as well as the quality value for each pane, every pixel with a size of 0,12 x 0,12 mm is being measured.

In collaboration with the Rheinisch-Westfälischen institute of technology Aachen – Ms. Dr eng. Ruth Kasper, Prof Dr eng. Markus Feldmann, Pietro die Biase and Benjamin Schaf – as well as the colleagues from the institute of technology Munich – Prof Dr eng. Christian Schuler and Steffen Dix – mathematical structures and the necessary technical basics have been initially acquired and developed. The result is an exact determination of the isotropic and anisotropic areas of a tempered lite together with a final quality result.

For a professional and comprehensive definition of the quality, it is also important to measure the edge stress along all edges of a specific lite.

By doing so, the LineScanner determines the edge stress levels and provides a precise result regarding the expected fragmentation pattern.

Only this unique and telecentric, provided by the Softsolution LineScanner, can offer a solution that includes every combination of quality check possible all within a single quality inspection system.

You are not logged in, please sign in to view contact

You are not logged in, please sign in to view contact Info release

Info release Promotion

Promotion Building shop

Building shop Online business

Online business