The Group’s innovative technology applied to chemicals for flat glass processing was center stage at the Italian glass industry trade show. From latest-generation coatings to digital printing, Fenzi offers a broad range of complete solutions for the international glass industry, once again proving it sets the standard for the entire industry.

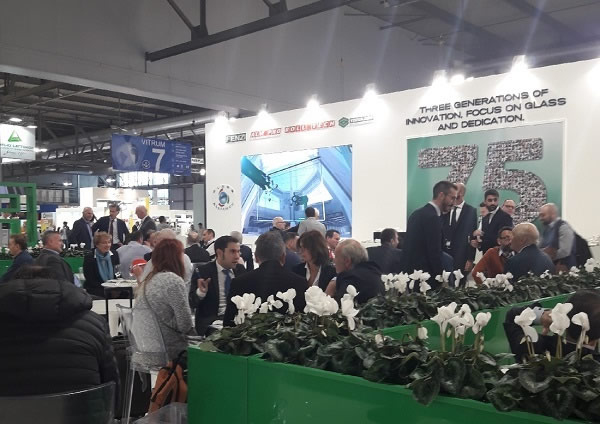

Vitrum 2017, the 20th edition of the show, paid off for the Fenzi Group with a huge turnout of Italian and international visitors interested in the many innovations on display.

In the words of Alessandro Fenzi, the Group’s CEO:

“Vitrum has proven itself to be a key event for us, capable of attracting visitors from across Europe and overseas. With 19 successful editions to its credit, Vitrum’s specialization allows it to focus in-depth on the most current areas of interest and to provide excellent opportunities for doing business with highly-qualified industry professionals”.

All the Business Units were distinctly represented at the show, starting with Side Kinetix, the latest technology in digital printing introduced by Tecglass – the Spanish firm that joined the Fenzi Group last year.

Side Kinetix is an innovation that has had a unique impact on the market – by changing the print direction on the glass, it ensures customers the advantage of greater production speed and efficiency.

The Tempver Automotive line of enamels for the automotive industry is the latest breakthrough in the glass enamels Business Unit. It is an initial, key development in a journey begun last year that is already richly rewarding the Fenzi Group.

Innovations also reign in the mirror-backing paints Business Unit which, in 1941, began leading the company to success and recently marked another milestone – the completion of the Luxver range with a line of products that spans the entire glass silvering process and strengthens Fenzi’s position as a global partner for all mirror manufacturers.

The insulating glass division, the largest in terms of size and revenue, is invested daily in the ongoing development of sealants and highperformance warm edge spacers for IG units, products capable of meeting the most restrictive standards set for the most cutting-edge systems.

“By focusing on the needs of the glass industry, we are able to offer high-tech products that consistently meet market demand for high-quality products – continues Fenzi. – We were pleased to note that our customers at the show were favorably impressed with the innovations on display”.

Side Kinetix: Digital Printing on Glass Changes Direction.

Tecglass makes printing on large glass sheets faster than ever. With the Vitro Jet F Type Side Kinetix model, the head moves crosswise to the print carriage.

This changes everything: even with glass sizes larger than the carriage, it’s possible to consistently print in the direction of the long side of the glass; that is, in the easiest and fastest manner. A truly unique technology for an even more versatile machine, one that dramatically increases print efficiency.

The advantages of the Vitro Jet F Type Range:

- All movements driven by high precision magnetic linear technology: the highest precision with no mechanical wear.

- Automatic glass positioning.

- Very easy and precise positioning of irregular shapes.

- Two independent belt stations integrated into the printing table increase productivity and reduce cycle time.

- The exclusive Fast Frame Printing Tool, ideal for IG units for frameless windows, solar panels, automotive glass and TV screens.

- High flow rate ink recirculation system: no ink residue on the heads, no need for cleaning

- SDT Simultaneous Drying Technology for automatic, simultaneous printing and drying.

- Print resolution: up to 1440 dpi

- VDS Technology: 7 levels of ink drop sizes for maximum speed and precision in every print application

- Vitro-Palette. Thousands of color formulations are ready to use. Choose from RAL, Pantone, NCS and many other Color-book formulations.

- Vitro-Catalog. A catalog of ideas, images and graphic designs always available on our website.

Luxver, ideal solutions for glass silvering.

The innovative Luxver product line was a headliner at Vitrum 2017. Experience in the field of mirror-backing paints (the first products it introduced more than 75 ago and still in continuous evolution), convinced Fenzi to expand the line of products it makes for mirror manufacturers around the world by developing a complete range of chemical products for the entire silvering process.

An extremely high-quality family of products that covers the entire mirror manufacturing process, it is easy and ready to use, and engineered to satisfy the highest safety standards. Available in all versions, including copper-free, Luxver is already the product of choice for many of the leading industry companies engaged in producing the best mirrors in the marketplace.

Tempver Automotive

When we are in an automobile, our needs for comfort and style are second only to the number one requirement -- the utmost in safety, in every way. Which is why, when the automotive industry processes glass, the Fenzi Group’s experience and ability to innovate play an essential role.

Fenzi’s Tempver Automotive glass enamels comply with the strictest quality standards and pass all the tests required by auto manufacturers in terms of both chemical and mechanical resistance. Their extremely high optical density means they provide the ideal coverage to optimize glass performance.

Fenzi paints are easy to apply, adapt perfectly to screen and digital printing and offer excellent performance in both press bending and gravity bending. Entirely free of heavy metals, they bring tangible and meaningful value to the term “eco-friendly”.

www.fenzigroup.com

You are not logged in, please sign in to view contact

You are not logged in, please sign in to view contact Info release

Info release Promotion

Promotion Building shop

Building shop Online business

Online business