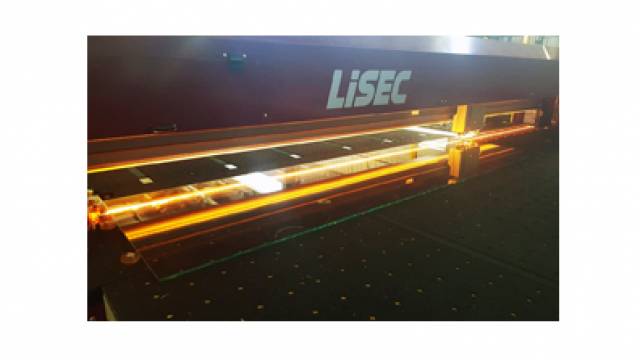

A LiSEC automatic cutting line with loading system was installed at Glass 360

A LiSEC automatic cutting line with loading system was installed at Glass 360, a newly formed glass processing company in Queensland, Australia. CEO Phil Norman explains why they chose LiSEC.

“Glass 360 was conceived to cater for small to medium sized glaziers, requiring a fast and reliable turnaround service,” says Phil. “I was aiming to reinvest into our industry and gain tangible assets in a company with genuine growth potential, founded on quality machinery and superior customer service.” Along with purchasing the best machinery, Glass 360 employs confident, experienced staff with a proven record in running a glass supply factory.

The business model for Glass 360 called for the installation of machinery and equipment with the capability to deliver maximum automation, accuracy and efficiencies throughout the manufacturing process. “For this major long-term investment, we required a machine offering value for money at the reliable end of the scale – we definitely didn’t want knock-offs,“ Phil confirms.

Extensive research was conducted before making the decision to purchase the LiSEC cutting line. “I investigated the topic by attending the glasstec trade fair in Düsseldorf 2016. The best advice my partner and I received was to go with LiSEC, which supplies high-performance machinery for a diverse range of jobs.“ notes Phil.

Before making the decision, the owners of Glass 360 met with the LiSEC team. “We met with Lee Thurbon and Sandro Ianni from LiSEC to se...

You are not logged in, please sign in to view contact

You are not logged in, please sign in to view contact Info release

Info release Promotion

Promotion Building shop

Building shop Online business

Online business