MetaShield has developed a nanoparticle-based coating that significantly enhances the impact resistance of glass

MetaShield has developed a nanoparticle-based coating that significantly enhances the impact resistance of glass. Such strength-boosting coatings could be useful in glass’s many applications, including automobile windows, mobile devices, windows, medical equipment, glass containers, eyeglasses, and more.

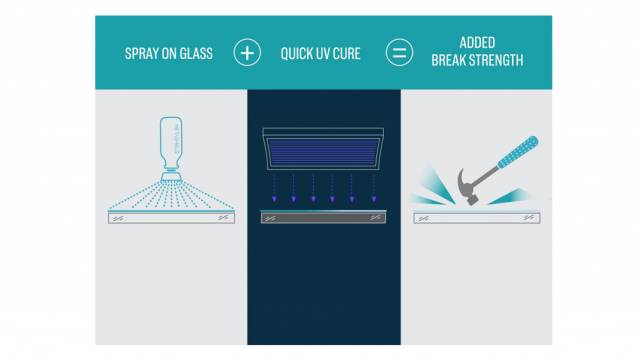

The transparent MetaShieldGLASS coating – applied via spray, dip, or flood coating and then cured with UV light – can be applied in just five minutes, the company says, and requires no fancy, specialized equipment. It’s designed for use with commercially available systems, making the potential opportunities quite attractive.

The company recently reported that results from independent testing of its MetaShieldGLASS coating reveal it significantly enhances the impact resistance of both untempered and tempered aluminosilicate glass.

The lab, InterTek, measured impact resistance – following standards developed by Asahi Glass to more accurately assess thin cover glass – by dropping a weighted ball from a specified height onto a test sample of glass. By testing many samples (here, n = 30) and measuring at what drop height each sample breaks, these drop-ball tests provide a relative measure of the average kinetic energy required to break each glass sample type.

The testing examined two kinds of glass: 0.55-mm thick untempered aluminosilicate glass, and 0.55-mm thick tempered aluminosilicate glass – better known as Corning’s Gorilla Glass 3.

These dynamic impact tests show...

You are not logged in, please sign in to view contact

You are not logged in, please sign in to view contact Info release

Info release Promotion

Promotion Building shop

Building shop Online business

Online business